There has always been a widespread need for electronic sensors that can handle a diverse range of physical phenomena, such as light, pressure, sound, and, of course, temperature (the most widely sensed parameter). The good news is that there have been significant advances in delivering high-performance, low-cost, easy-to-use sensors for many of these measurements, with progress often based on microelectromechanical systems (MEMS) technology. For example, sensing of position and motion—two closely related physical attributes that are traditionally among the most challenging to measure—is now almost trivial due to the widespread availability of tiny silicon-based accelerometers and gyroscopes, which are widely used for navigation in drones and for car safety.

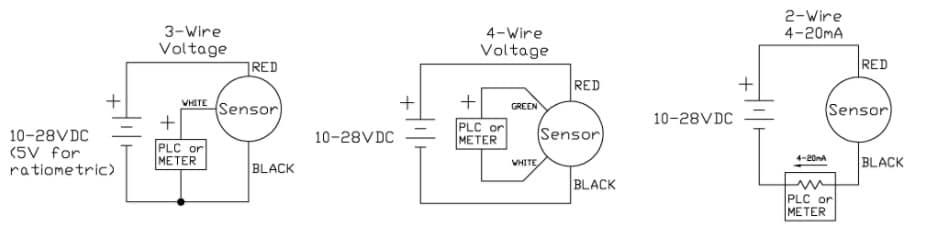

Still, one sensing area has long eluded the development of high-performance, low-cost, low-power sensors: vapor and gas (smell) sensing. We are still a long way from a sensitive, universal odor-sniffing capacity equating that of a beagle’s or even a human’s nose. Sensors for gases, volatile organic compounds (VOCs), and even humidity have been especially challenging to develop, and they have been harder to use, calibrate, and integrate than temperature sensors. Further, each gas sensor often has a different analog output format that involves scaling, voltage versus current, timing, and other variations (Figure 1).

Figure 1: Different analog interfaces are commonly used for sensors, including the three-wire voltage, four-wire voltage, and two-wire 4mA to 20mA current outputs. Integrating a set of different sensors can become a challenge for analog input/output (I/O). (Source: TE)

The problem is aggravated when it is necessary to measure multiple, distinct variables at a single location. Simply and successfully interfacing with the diverse variety of available sensing solutions requires limiting sensor choices, adding adapter circuits to yield a single output format, or interfacing with multiple output formats.

Throughout the last decade, though, there has been significant progress, as MEMS and associated semiconductors have been radically changing the situation and providing low-power, low-cost sensors for specific gases. However, these advances began with application-specific impact and pressure sensors for air bag triggering, as opposed to with gas sensors. This research, development, and commercialization has opened the way for progress in MEMS sensors regarding pressure, VOCs, and carbon dioxide (CO2). The result has created widespread availability of microchip-based devices for basic sensing of gases and liquids as well as for calibration, additional integrated features, and more embedded functions.

Trend: Single-Point, Multi-Factor Sensing

As sensors have advanced in terms of their basic performance, ease of interconnect, cost, and power requirements, there has been a corresponding trend of sensing multiple parameters at each location. This is a departure from previous architectures where only temperature (and perhaps humidity) were sensed and measured at one location, and VOCs and CO2 were sensed at another, for example. With the newer sensors, it is feasible and actually makes sense to integrate a full set of sensors at each site with single-path (wired or wireless) connectivity.

Doing so serves various applications that need sensor data across multiple parameters. These include lighting control, building automation, security, motion and presence sensing, smart homes, connected homes, air quality monitoring, and energy management. Further, by combining the full roster of desired sensors into a single device, system designers, their projects, and even the end-users benefit from a reduced time to market, fewer design “surprises,” and reduced installation costs, because designers no longer need to deal with individual sensors and interfaces (unless they need to or want to do so). This enables low-cost, convenient placement of multifunctional environmental-sensor nodes in industrial, commercial, institutional, and residential settings.

Leveraging this new multisensory opportunity, vendors have developed small boards and modules that offer a selection of commonly needed sensing functions, as complete, highly integrated, calibrated, and easy-to-use solutions for these applications. Two products demonstrate how change in the integrated sensing of multiple physical variables, including gas-based variables, is greatly simplifying challenges as well as opening new opportunities. These include the:

TE Connectivity AmbiMate Sensor Module MS4 Series

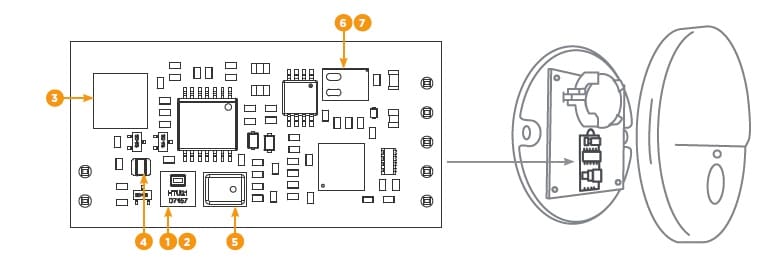

This unit from TE Connectivity targets fixed-in-place installations, such as buildings, and is packaged on a PC board that measures a mere 16mm × 30mm (Figure 2). TE Connectivity’s AmbiMate Sensor Module MS4 Series enables the sensing of well-known environmental and presence parameters of motion via a passive infrared (PIR) detector, light, temperature, and humidity. It also offers optional microphone-based sound detection, VOC sensing for ambient air quality and hazardous conditions, and CO2 sensing (Figure 3).

Figure 2: The AmbiMate Sensor Module from TE Connectivity is a small PC board intended for fixed installations. (Source: Mouser)

Figure 3: The AmbiMate Sensor Module board is housed in a user-provided enclosure. Included on the board are sensors for (1) temperature; (2) relative humidity; (3) motion; (4) ambient light; (5) audio microphone (optional); (6) VOCs (optional); and (7) CO2 (optional). (Source: Mouser)

The AmbiMate Sensor Module operates from a single 3.3VDC supply (which is nominal, with a 3.1V minimum) and requires just 10mA (or 33mA with the VOC/CO2 sensing option) for low dissipation, high reliability, and long operating life from a local battery. Accuracy for the temperature reading is ±0.3°C from 5°C to 50°C, while the accuracy of its humidity reading over the five percent to ninety-five percent relative humidity (RH) range is two percent. Both temperature and humidity sensors have 1s update rates.

For the gas sensing functions, the unit can handle VOCs with concentrations from 0 to 1,187 parts per billion (ppb) and CO2 readings from 400 to 8,192 parts per million (ppm). Both gas-related readings have 60s acquisition periods.

The module can be queried at any time via its 100kbaud inter-integrated circuit (I2C) interface, and it also includes an interrupt-driven event pin for motion- and sound-level detection, with a response time under 0.5s. The audio-alarm output has a sensitivity of between -25dBV and -19dBV over a frequency range of 100Hz to 10kHz.

Bosch Sensortec BME680 Integrated Environmental Sensor

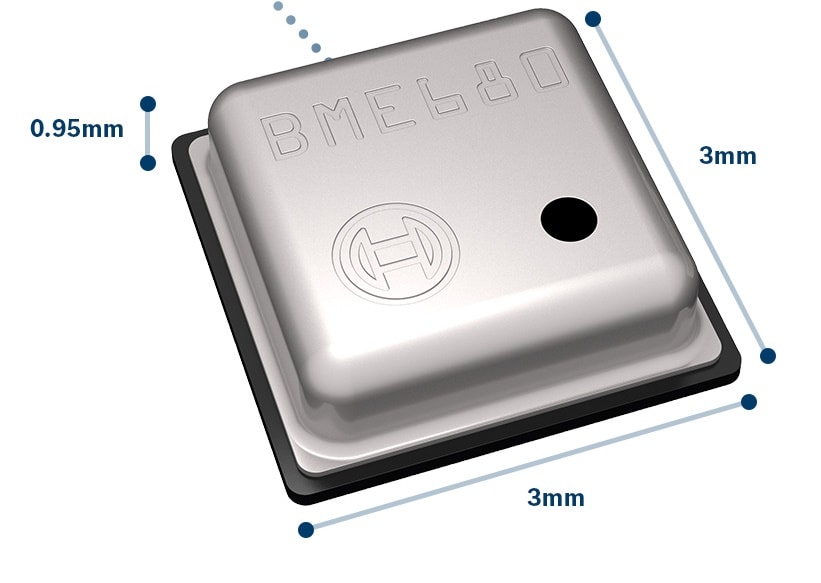

In contrast to the AmbiMate module, the Bosch Sensortec BME680 Integrated Environmental Sensor

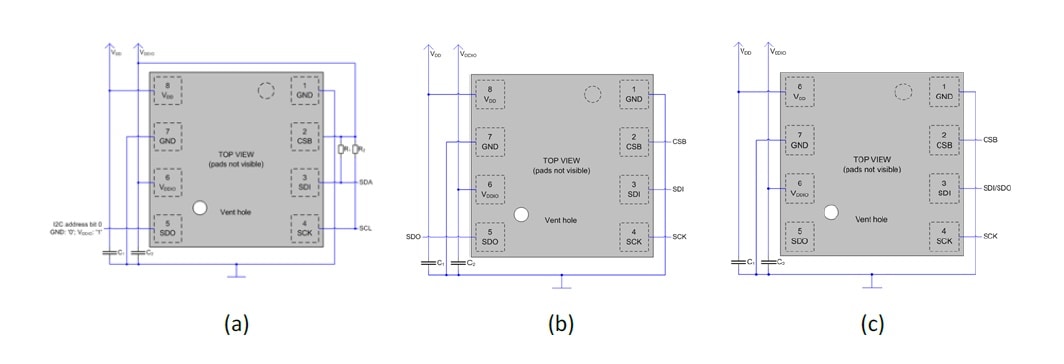

unit integrates high-linearity and high-accuracy gas, pressure, humidity, and temperature sensors in a package developed specifically for mobile applications and wearable devices. The tiny metal-lid land grid array (LGA) enclosure has a 3mm × 3mm footprint and is just 0.95mm high (Figure 4). To ease interfacing with different processor configurations, it supports one I2C and two serial peripheral interface (SPI) I/O formats (Figure 5).

Figure 4: The Bosch Sensortec BME680 Integrated Environmental Sensor for mobile and wearable devices is a nearly invisible 3mm × 3mm metal-lid device, yet it includes an array of sensors, calibration, and I/O functions within the enclosure. (Source: Bosch)

Figure 5: To facilitate connectivity between the BME680 and its host processor, the unit includes the three commonly used low-power options, which are the: (a) I2C interface; (b) four-wire SPI; and (c) three-wire SPI. (Source: Mouser)

The BME680 is well suited for sensing VOCs in paints, lacquers, paint strippers, office equipment, glues, adhesives, and alcohol. It includes embedded calibration, and in addition to ethanol, the sensors also test exhaled human breath for VOCs and important compounds (Table 1).

Table 1: The detailed data sheet for the BME680 includes a table of its tolerance and accuracy when sensing the most-common VOCs. (Source: Bosch)

| Molar Fraction | Compound | Production Tolerance | Certified Accuracy |

| 5ppm | Ethane | 20% | 5% |

| 10ppm | Isoprene (a.k.a., 2-Methyl-1,3 Butadiene) | 20% | 5% |

| 10ppm | Ethanol | 20% | 5% |

| 50ppm | Acetone | 20% | 5% |

| 15ppm | Carbon Monoxide | 10% | 2% |

The gas-sensing function of the BME680 demonstrates the level of integration and sophistication that is embedded in this miniscule device. This function involves two steps:

- An integral gas-sensor hot plate is heated to a target temperature, typically between 200°C and 400°C, and sustained for a required time period.

- The resistance of the gas-sensitive layer of the sensor is measured, and this resistance value is then mapped to a corresponding value of VOC concentration.

In developing this device, every effort was made to minimize power consumption—a critical parameter for mobile and wearable applications. Therefore, the device operates from a 1.71V to 3.6V supply. Current requirements are in the single-digit microamp range for each sensor (1Hz update rate), with an increase to about 12mA for the active gas-sensor mode; quiescent current is miserly at under 0.1mA in ultra-low-power mode and 0.15μA in sleep mode.

Conclusion

There is no longer a need for original equipment manufacturers (OEMs) to identify, buy, mechanically and electrically integrate, and code multiple sensors from different sources. Highly integrated MEMS and semiconductor devices enable placement of multiple sensors for different physical variables in a single, tiny, low-power package. Even the challenge of sensing VOCs and CO2 has been largely overcome due to these technological advances. Sensor and system performance is assured and known (as these devices come with detailed specifications), circuit interfacing is greatly simplified, and system integration is streamlined via software drivers and tools.

« Back to HomepageLatest News

- Maxim’s highly accurate Battery Fuel Gauges are needed to avoid surprise shutdowns and for a positive user experience

- Texas Instruments' diode LM66100 5.5 V, 1.5 A 79 mΩ, Low-IQ Ideal Diode

- Air-Quality Sensors: Redefining Environmental Sensing

- Medical

- Empowering

- Automotive

- RENESAS SYNERGY PLATFORM-Renesas Electronics丨5Star

- BCR401U, BCR402U, and BCR405U LED Drivers-Diodes丨5Star

- 800 V CoolMOS? P7 Power Transistors-Infineon Tech丨5Star

- 1200 V Silicon Carbide (SiC) Diodes, MOSFETs, and Modules-ROHM丨5Star

- SiHH26N60E, SiHH21N60E, SiHH14N60E, and SiHH11N60E MOSFETs-VISHAY丨5Star

- Industrial Motion Sensors STMicro’s sensors take motion sensing in industrial applications to the next level-STMicroelectronics丨5Star

- AWR1642 and IWR1642 FMCW Radar Sensors-Texas Instruments丨5Star

- BCPxT/BCPxH Series Transistors-Nexperia丨5Star

- NCV816x and NCP16x Ultra-High PSRR LDO Regulators-ON Semiconductor丨5Star